CNC (Computer Numerical Control) turning is a behind-the-scenes hero in the aerospace and automotive sectors, where precision engineering is paramount. This technology, driven by computer-controlled lathes, fabricates intricate components from various materials. In this article, we will delve into the profound impact of CNC turning in these industries.

Precision Component Manufacturing

Aerospace and automotive industries rely heavily on CNC turning for precision component manufacturing.

In aerospace, CNC turning is indispensable for crafting critical parts like engine components, landing gear elements, and hydraulic systems. These parts demand extreme precision and impeccable surface finishes to ensure safe and optimal performance in the rigors of flight.

Similarly, in the automotive sector, CNC turning is extensively used for manufacturing engine parts, transmission components, suspension elements, and other critical parts. The consistency and precision offered by CNC turning are vital for ensuring vehicle reliability and performance across the automotive spectrum.

Material Versatility

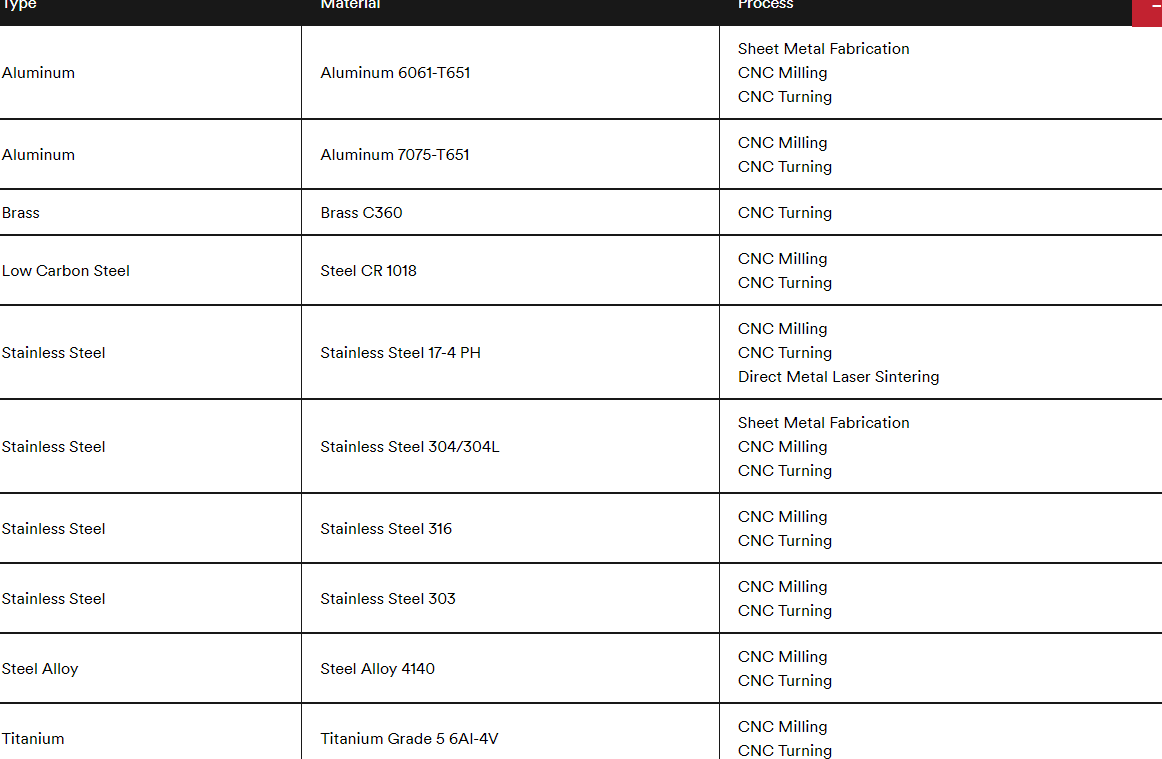

CNC turning's versatility shines through in its ability to handle a wide range of materials while maintaining precision and material integrity.

Aerospace relies on specialized materials, each with unique properties. CNC turning machines are well-suited to work with these materials, ensuring structural and functional integrity.

In the automotive industry, while metals like steel and aluminum dominate, modern vehicles incorporate plastics and composites for weight reduction and enhanced fuel efficiency. CNC turning adapts to these materials, offering a comprehensive solution for automotive component manufacturing.

Efficiency and Cost Reduction

Efficiency and cost control are perennial objectives in both industries, and CNC turning contributes significantly to achieving these goals.

In aerospace, CNC turning streamlines processes, reducing lead times and minimizing material wastage. It also enables the production of lightweight components, a critical factor in improving fuel efficiency and operational performance.

In the automotive sector, CNC turning enhances cost-efficiency through automation and reduced scrap rates. This is particularly vital in an industry striving to optimize manufacturing processes to stay competitive in a cost-conscious global market.

Customization and Prototyping

Innovation and customization are driving forces in aerospace and automotive engineering. CNC turning facilitates rapid prototyping and tailored component production to meet the industries' unique requirements.

In aerospace, CNC turning plays a pivotal role in prototyping and creating custom components for experimental aircraft, research, and development. It enables quick design iterations and the precise fabrication of one-of-a-kind parts.

In the automotive realm, CNC turning serves not only mass production but also supports the prototyping of new vehicle models and the development of custom parts for specialty vehicles, catering to diverse consumer demands.

Maintenance and Repairs

Beyond initial manufacturing, CNC turning has a vital role in the maintenance and repair of components and parts, extending the lifespan of critical systems.

In aerospace, CNC turning is essential for repairing and maintaining aerospace components, refurbishing critical parts, and reducing the need for costly replacements. This ensures the ongoing safety and reliability of aircraft.

Similarly, in the automotive industry, CNC turning is employed for refurbishing engine components and other crucial parts, contributing to the longevity and reliability of vehicles on the road.

Quality Control

Both industries prioritize quality control, and CNC turning is accompanied by rigorous quality control processes, including precision measurements and inspections, to ensure that components meet the highest standards for safety and reliability.

In aerospace, where safety is paramount, CNC turning's precision and quality control measures are instrumental in producing components capable of withstanding the demanding conditions of flight.

In the automotive industry, quality control is crucial to meeting industry standards and ensuring consumer safety. CNC turning plays a pivotal role in producing consistent and accurate parts that contribute to overall vehicle quality.