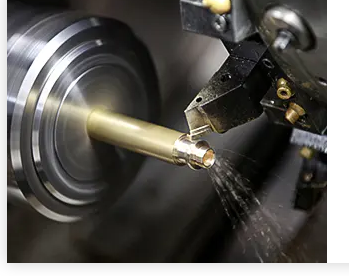

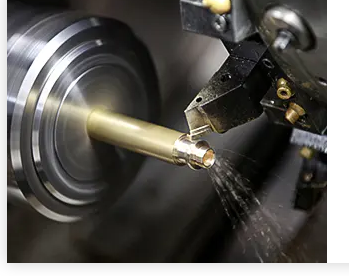

Precision CNC machining is a manufacturing process that utilizes computer-controlled machines to produce high-quality parts with extremely tight tolerances and complex geometries. This technology has revolutionized the manufacturing industry, allowing for faster production times, greater accuracy, and increased consistency in part production.

The CNC (Computer Numerical Control) machine is operated by a computer program that controls the movement of the cutting tool, which removes material from the workpiece to create the desired shape. This process is highly automated and precise, allowing for the creation of parts with very tight tolerances and complex geometries.

One of the key benefits of precision CNC machining is its ability to produce high-quality parts consistently. The computer program controls the machine's movements, ensuring that every part produced is identical to the one before it. This consistency is critical in industries such as aerospace and medical device manufacturing, where even small variations in part dimensions can have significant consequences.

Precision CNC machining also allows for faster production times than traditional manufacturing methods. Because the process is automated, it can run around the clock, producing parts at a much faster rate than manual machining methods. Additionally, the ability to program the machine for specific parts means that setup times are reduced, further increasing efficiency.

Finally, precision CNC machining can produce parts with complex geometries that would be difficult or impossible to create using traditional machining methods. This opens up new possibilities for designers and engineers, allowing them to create parts that are lighter, stronger, and more efficient.

In summary, precision CNC machining is a key technology for producing high-quality parts with tight tolerances and complex geometries. Its ability to produce parts consistently, quickly, and with high accuracy has made it an essential tool in many industries, from aerospace to medical device manufacturing to automotive engineering.